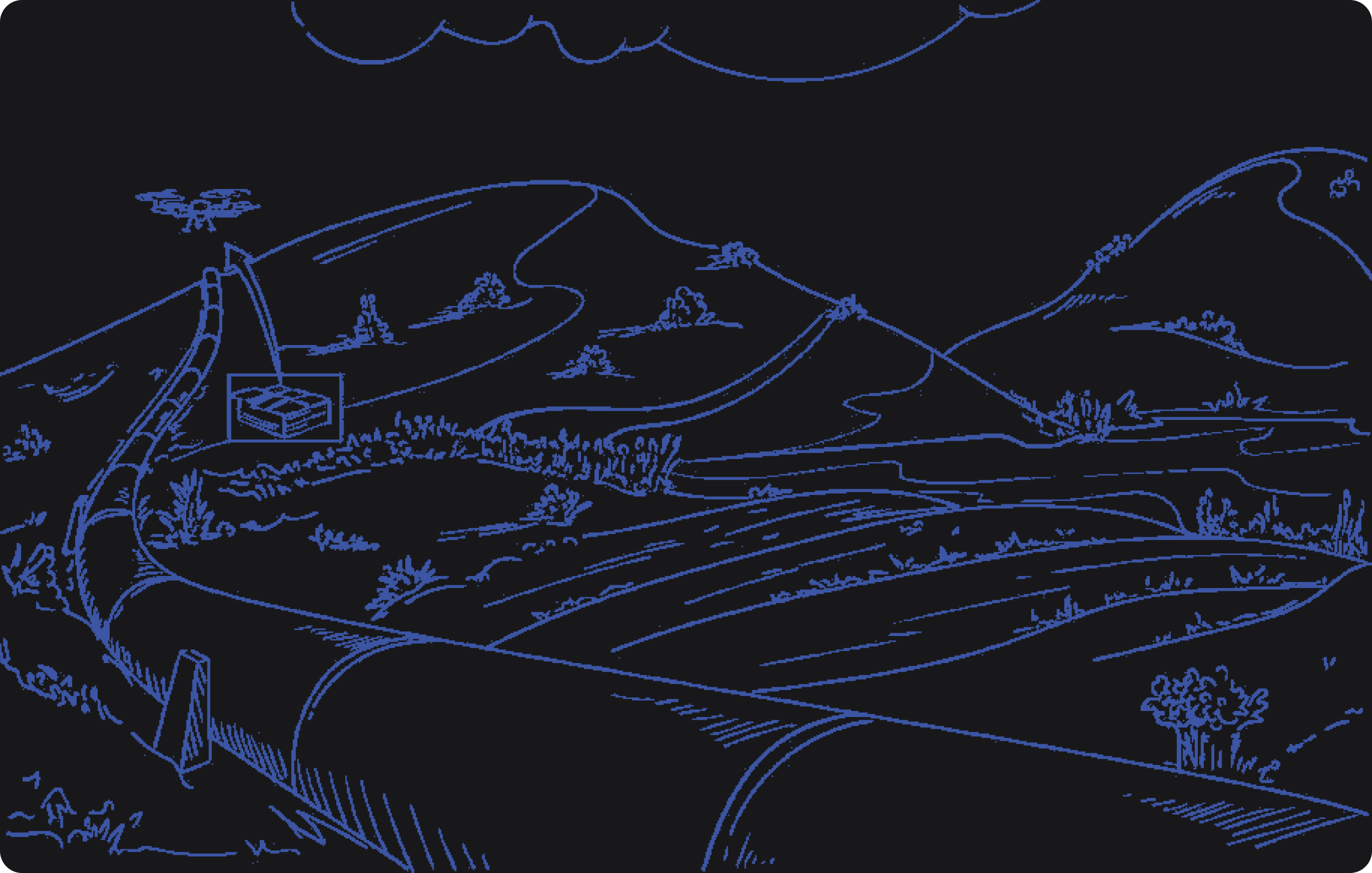

Gas Pipeline

How our drones help

Oil pipelines are vast infrastructures often in difficult terrains such as marshlands, hot desserts or frozen areas, or even areas of conflict.

Pipelines get monitored against various parameters, such as pipeline pressure and temperature, diameter of a pipeline rapture, layout of pipelines and type of transported fluid, etc.

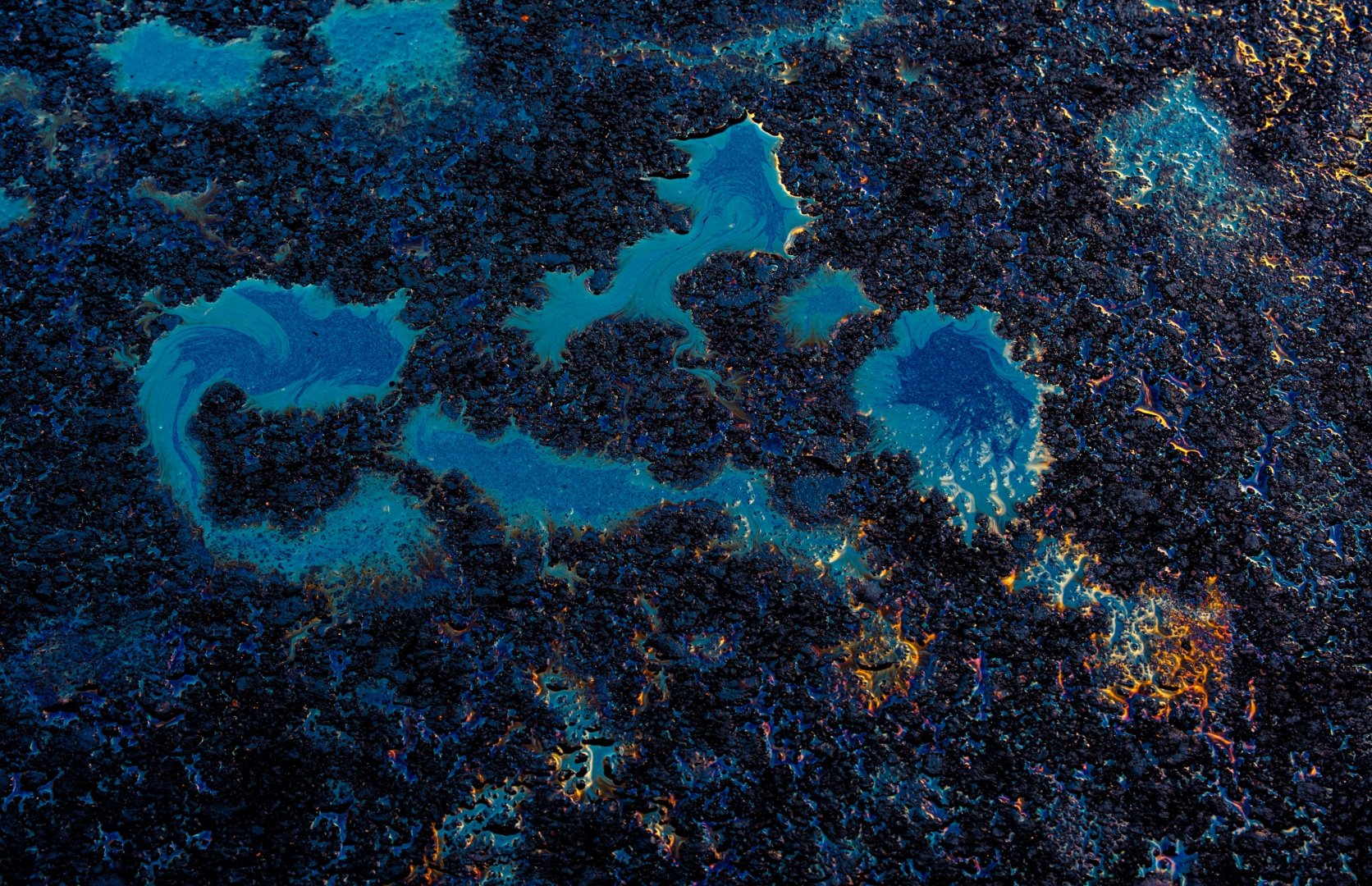

While pipeline operators must carry out regular inspections of their equipment to ensure it is in safe working order, restrictions in detection of hidden leaks may result in liquid hydrocarbons getting into the ground up to the water bearing-layer.

The length of main pipelines in Russia exceeds 280 thousand kilometres while in America it exceeds 2,2million kilometres. And the world’s economies depend on these critical supplies of energy.The extent of this infrastructure makes it hard to identify leaks in advance to avoid damages that can result.

Limitations of Pipeline Monitoring without Drones

Physical Patrols

- Difficult to detect leaks visually, or by smell.

- Human inspections can only go so far as people are often limited when it comes to heights or confined spaces.

- Inspection are constrained to pre-determined routes based on statistically sampling, leaving certain pipeline areas un-inspected.

Pressure Control Method

- Difficult to detect small leaks

Ultrasonic Flowmeters

- Difficult to detect small leaks

- Expensive

Conductive Cabels

- Difficult to detect small leaks

- Expensive

Helicopter or Plane

- Flies higher and quicker and has to carry heavy and expensive monitoring equipment

- Cost of pilot

- It still provides comparatively low resolution images for the same money

Earth Remote Sensing Data (Via Satellites)

- Low resolution images

Sensor Payloads for Drones in Pipeline Monitoring

Different high quality sensors aboard the unmanned aerial vehicle (UAV), allow simultaneous inspecting of pipelines with respect to different criteria. UAV’s light weight provides for continuous scanning providing maximum safety at the same time. UAVs ensure scanning of a pipeline at long distances and in hard-to-reach areas. UAVs can routinely fly closer to the ground at night, follow a very precise flight path, have lower operational costs and are more environmentally friendly.

Nextech recommends for drones in pipeline monitoring that end users should identify the type of data that needs to be collected first, ie:

In various combinations the above technologies can be used in the following methods for drones in pipeline monitoring:

Multispectral Imagery to Identify

- Monitoring pipeline right of way. Can be used in an agricultural space to detect plant health, but conversely it can be used to see the effect of pipe line on ecosystem and identify gas leaks.

- Occupying and damaging vegetation

Lidar To Create 3D Digital Model

- Due to the high accuracy of Lidar models you can make 3D models (digital twins) of pipeline and its relation to the first digital model of when the pipeline was installed to work out where the pipeline has shifted to after time and predict possible damage and modify pipeline to pre-empt damage that can occur.

Thermal Identify Possible Defects

- Difficult to d

- Expensiveetect small leaks

Helicopter or Plane

- Using general wave cameras using RGB imagery and thermal overlay you can predict weaknesses in pipes and possible leaks and send out inspection teams to measure if there is an actual leak or a bigger heat-shift reflecting structural failure.

Earth Remote Sensing Data (Via Satellites)

- Low resolution images

The above requirements will greatly aid to identify the appropriate platform for pipeline monitoring

- A small quadcopter which make it possible to obtain maximum details for medium and small areas to ensure detailed scanning of subsurface pipelines

- A larger fixed wing can meet larger requirements but provide lesser resolution and detail

The Future

Technology changes at a rapid pace and recently there have been exciting advances with more sensitive methane detection sensors on UAV platforms that can get closer to the sources of pipeline gas leaks. These game changing developments are increasingly getting the attention of more and more gas pipeline operators who are prioritizing these for adoption

Transforming Pipeline Monitoring with AI and Drone technology

“AI is the new Electricity”

Often compared to the introduction of electricity which transformed industries in the 1800’s, or even the. Discovery of fire about 2 million years ago, Artificial Intelligence (AI) is already transforming society, creating massive change and huge economic value. The Oil and Gas industry, Pipeline Monitoring in particular, is deriving great benefit from the implementation of BOTH Drone Technology and AI.

AI is able to generate insight without human intervention, or limitations, by learning from masses of data which is processed at astronomical speeds. The more data, the more actionable the insights. AI finds out what works, and then amplifies this beyond human ability to do so.

Drones overcome traditional pipeline monitoring limitations by taking powerful, multi-sensor payloads, to very close to the pipeline and generating higher volumes, of much richer data in terms of context, and resolution, providing the masses of data for AI engines to process.

Being able to remotely perform many maintenance tasks is a huge benefit to this capital-intensive industry, being amongst the most complex of industries having to deal with stringent guidelines regarding safety, health, and environment.

False Alarms

Often traditional systems generate false alarms and nothing significant which can lead to alarm fatigue, where people do not respond. The problem is that when something happens with the transportation of dangerous fluids, it can very serious and have catastrophic consequences.

Threshold-based

Another major challenge with threshold-based alarm systems is reporting exceptions after the fact and with limited insight into the cause

UAV-Based Sensor Payloads Used for Pipeline Monitoring

Effective pipeline monitoring strategies should take into account: type of inspection data, inspection methods and types of UAV platforms.

Types of inspection data:

The value of data is, especially for AI applications, is emphasized by the often-quoted phrase: “Data is the new Oil!” A variety of rich data sources can used to monitor various aspects of long-distance pipeline infrastructures.

High-resolution colour imagery

Multispectral imagery

LiDAR

Thermal

Emerging Technologies

Technology changes at a rapid pace and recently there have been exciting advances with more sensitive methane detection sensors on UAV platforms that can get closer to the sources of pipeline gas leaks. Oil & gas operators have been able to digitize several aspects of their value chain with a variety of recently emerging technologies.

Artificial Intelligence

- Using AI’s pattern recognition to differentiate the different vibrations can create a multi-dimensional vibration pattern of different events on the pipeline.”

- Using AI on the edge for pipelines, the algorithm can detect that granular differences between different types of impacts and can detect with high confidence over the majority of the incidents,”

Edge computing

- Using several technologies like embedding of the sensor, storage, compute, advanced artificial intelligence, (machine learning) where intelligence will move towards the edge of various endpoint devices installed in oil & gas companies.

- These technologies connected through 5G networks, along with technologies such as IoT, cloud computing, and robotics are digitally transforming the industry.

Drones

Drones, capable of integrating various payloads, sensors, and imaging technologies, effectively carry out operations like important Methane Gas leak detections, as well as corridor mapping, emergency response, and recovery, etc. in the oil & gas sector.

Intelligent video surveillance systems

CCTV cameras when integrated with AI enable more advanced solutions like face recognition, object recognition, event recognition, intelligent image processing, remote asset management, behavioural detection, and analytics.

Image analytics

AI allows the use of image analytics to monitor any deformation from the baseline profile of infrastructure. The real-time visibility of infrastructure integrity ensures safe operations, while also reducing the cost and human errors in meter reading.

Digital Twins

- At its simplest level a digital twin is a concept whereby a digital replica of a physical facility is developed and can be a digital proxy of the physical world.

- At the same time a digital twin is also represents the culmination of all the other digitalisation efforts, combining the benefits of these efforts into one single 3600 experience and source of information for all stakeholders from engineering to finance and marketing.

- By combining available operational data from existing SCADA systems, Pipeline Applications and ERP systems along with Multi-Sensor Data integration insights can be can be generated via an AI engine that predict asset failures and improve processes safely, as well as identify business opportunities.

Integrated Solutions

Leakage detection represents the most critical element of the Oil & Gas industry inspection and detection for preventing major accidents as well as avoiding malfunction of equipment. Major techniques include:

01

Multi-sensor Data Integration that allows modelling of vital equipment such as flowmeters and valves using AI, as well as ensuring that detection is validated with more than one type of data. For example, in an oil pipeline, you would want to analyse the flow and improve corrosion, as well as identify and pinpoint potential leaks.

02

By utilising both AI and Edge Computing detect and alert central operations to potential issues such as leaks, corrosion, freezing damage or vandalism. It also allows operators to capture and analyse remote operations through image analytics. But above all it adds intelligence by predicting and optimising pipeline maintenance and integrity.

03

A Digital Twin of a physical plant or asset can be used to optimize various processes before implementation on the physical asset and also make adjustments to facility designs. Different sensor types and devices may be integrated with the software to build digital profiles, and then used to predict and optimize pipeline maintenance and integrity.

04

In this regard, sensors are deployed capable of collecting information about unwanted gas leaks to avoid losses of human as well as other infrastructures and are not only capable of generating alerts but also providing information to actuators to act automatically in order to stop the leakage and mitigate the consequences.

The Benefits of Leveraging AI

Combining the intelligent algorithms in AI with an end to end solution that integrates sensors with real-time edge computing for profiling of assets and activities is ideally suited for not only Pipeline Monitoring but the Oil and Gas as a whole. Along with the digital twin design this enables a model-focused approach that allows prompt insights into operational conditions enabling safe, preventative maintenance, continuous process improvement and responsive commercial strategies.

Nextech is a long-range UAV manufacturer that specialises in solutions for the Oil and Gas industry.